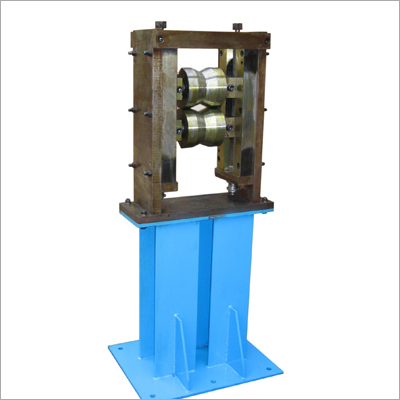

Drive Roller Assembly

Drive Roller Assembly Specification

- Power Source

- Electric motor driven

- Belt Type

- Flat belt or modular belt compatible

- Surface Finish

- Powder coated or galvanized

- Thickness

- Roller shell thickness: 3 mm to 5 mm

- Material

- Mild steel or stainless steel as per requirement

- Type

- Drive Roller Assembly

- Belt Conveyor

- Suitable for belt conveyor integration

- Roller Conveyor

- Designed for powered roller conveyor systems

- Vertical Conveyor

- Compatible integration available

- Resistant Feature

- Corrosion and wear resistant surface treatment

- Load Capacity

- Up to 1500 kg depending on roller size and material

- Voltage

- 220V/380V AC, customized options available

- Power

- 0.75 kW to 2.2 kW (variant dependent)

- Speed

- Adjustable, typically 1040 m/min

- Usage & Applications

- Material handling, packaging, assembly lines, logistics

About Drive Roller Assembly

Features:

-

Precise dimensions

-

Easy to install

-

Sturdy construction

-

Longer service life

Superior Load Capacity and Material Options

Built to handle loads up to 1500 kg, the Drive Roller Assembly is available in either mild steel or stainless steel, offering adaptability to different operational demands. The robust construction increases longevity and reliability, ensuring efficient performance under heavy-duty conditions.

Versatile Integration and Adjustable Performance

Compatible with both belt and powered roller conveyor systems, this drive assembly also supports vertical integration. Users benefit from adjustable speed settings and voltage flexibility (220V/380V AC), making it an ideal choice for diverse industrial setups and high-throughput requirements.

Corrosion and Wear Resistance for Extended Service Life

A specialized surface treatment, such as powder coating or galvanization, enhances resistance to corrosion and wear. This feature supports ongoing durability, minimizing maintenance requirements and extending product lifespan in challenging environments.

FAQs of Drive Roller Assembly:

Q: How is the load capacity of the Drive Roller Assembly determined?

A: The load capacity of up to 1500 kg depends on the size and material of the roller selected (mild steel or stainless steel). Proper configuration based on specific application requirements ensures optimal load handling and long-term reliability.Q: What types of conveyor systems can this assembly be integrated with?

A: The Drive Roller Assembly is designed for seamless integration with both belt conveyors (flat or modular belt) and powered roller conveyor systems. It also supports vertical conveyor applications, providing versatile installation options.Q: When should I consider using a corrosion and wear-resistant surface finish?

A: Corrosion and wear-resistant finishes, such as powder coating or galvanization, are recommended for operations in harsh or humid environments and wherever consistent durability is essential to prevent equipment degradation over time.Q: Where is this Drive Roller Assembly commonly applied?

A: This assembly is widely used in material handling, packaging, assembly lines, logistics centers, and other industrial sectors across India and internationally, where efficient and robust conveyor systems are vital.Q: What is the process for selecting the right drive assembly configuration?

A: Selection involves assessing load requirements, conveyor type, speed range, environmental conditions, and power supply. Customizable features ensure that each drive roller can be specified to fit unique operational demands.Q: How does adjustable speed benefit conveyor system operations?

A: Adjustable speeds (1040 m/min) allow for precise control over material flow, enabling operators to match line speeds with production needs and improve overall system efficiency.Q: What are the main advantages of choosing this Drive Roller Assembly?

A: Key benefits include high load capacity, versatility in conveyor integration, robust corrosion and wear-resistant construction, customizable power and speed options, and reliable performance in demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Assembly Category

Plate Centering Roller Assembly

Usage & Applications : Industrial material handling, steel plate alignment

Type : Other, Plate Centering Roller Assembly

Surface Finish : Powder Coated / Galvanized

Material : Mild Steel with Zinc Plating

Belt Conveyor : Other, Compatible with standard belt conveyors

Roller Conveyor : Other, Included

Idler Roller Assembly

Usage & Applications : Material handling, mining, cement, power plants, conveyor systems

Type : Other, Idler Roller Assembly

Surface Finish : Galvanized/Powder Coated

Material : Mild Steel, Rubber, Stainless Steel (depending on configuration)

Belt Conveyor : Other, Compatible

Roller Conveyor : Other, Compatible

Roll Invert Assembly

Usage & Applications : Roll turning, positioning, and transferring in material handling and packaging industries

Type : Other, Roll Invert Assembly

Surface Finish : Powder Coated / Painted

Material : Mild Steel with Powder Coating

Belt Conveyor : Other, Not Included

Roller Conveyor : Other, Yes, Heavy Duty Rollers

Vertical Guide Roller Assembly

Usage & Applications : Side guide for vertical conveyors, Material handling systems, Elevators, Lifts

Type : Other, Vertical Guide Roller Assembly

Surface Finish : Zinc plated, Powder coated

Material : High grade Mild Steel (MS), Zinc plated and/or powder coated

Belt Conveyor : Other, Compatible with side belt guidance

Roller Conveyor : Other, Compatible

Send Inquiry

Send Inquiry